Miniquantum

Sergey Shirogorov

Feb. 2023

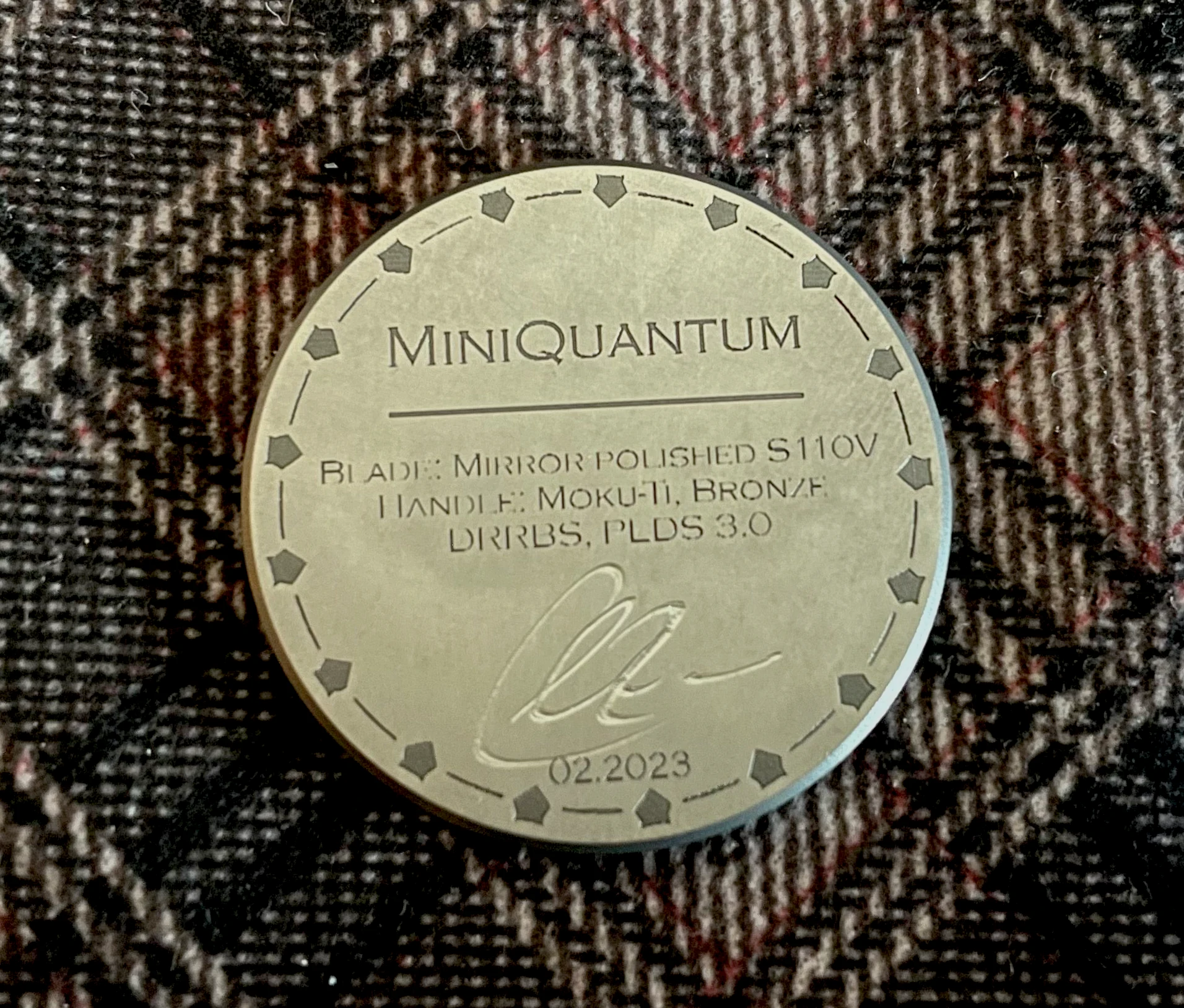

Sergey Shirogorov is one of those knifemakers who should need no introduction at this point. Hailing from Yaroslavl, Russia, he is well known for making computer-assisted folding knives to an impeccable standard in even his production lineup, his limited Custom Division knives raise the bar in craftsmanship and are highly sought after. His full custom knives come in unique configurations and exotic materials. This custom Miniquantum was won by me at an auction for ███████. Included is an embroidered cloth with lanyard, and titanium coin which is its certificate of authenticity.

Blade

The blade is mirror polished steel, CPM S110V, which is typically heat-treated to 63 HRC. The difficulty in polishing such a hard steel makes it a very time consuming process. All of its exposed bevels are polished to a fine mirror. The face of the edge is very short and not so steep, which helps with edge retention.

The blade profile is what's known as a Persian style, where the tip is curved up and pointy at the end. The grind is flat and triangular, as opposed to a hollow grind which some prefer for better slicing, at the cost of rigidity. It has a pierced fuller and flipper tab, which is mostly for looks. The choil is quite minimal, not like one will put this knife to enough hard use to sharpen often anyways.

Handle

Most of the brilliance of this knife is in the handle, which is not only gorgeous on the outside, but also on the inside. The material is MokuTi, short for Mokume-gane Titanium. Mokume-gane is a Japanese method of metalworking which layers different types of metals together to form a pattern. In this case, it is two grades of titanium, which is then heat treated and/or anodized to exhibit the black and bronze colors. The backspacer and pocket clip are made of actual bronze.

Inside the handle is most complex, there is milling on the inside to save weight, and the pivot assembly is inlaid into the scales. There is also the lock bar, which is made of steel and attached to the scale with two screws and a pin. This is sort of a hybrid between a liner lock and a frame lock, and the lock bar being covered by the scale means that one doesn't have to worry about putting tension on the lock bar while deploying the blade. The lock bar also provides tension for the Rotating Pocket Clip, which allows the clip to fit on thick cloth and provides good retention.

The pivot is known as PLDS 3.0, or Pivot Load Distribution System. It uses an internal bushing which provides counter-rotational force to the pivot. There are also two rows of very small roller bearings, which is rather unique in the knife world. This pivot provides the smoothest action of any knife I have ever handled, which is quite a compliment. Everything about this knife makes it extremely fidget-worthy.

Disassembly

Warning: don't do what I did and disassemble this knife. I had designed custom bits which fit into the duckfoot pivots and had them machined. The bits work for disassembly, but putting it back together is where the danger is. I had accidentally over-torqued the main pivot by not using a torque driver, which damaged the pivot assembly.

For such a pricey knife, one would expect service to be as pricey, but Sergey promises to service any of his full custom knives free of charge, and he honoured it. In my case, this knife came back with a brand new pivot assembly, after I had just about destroyed the old one.